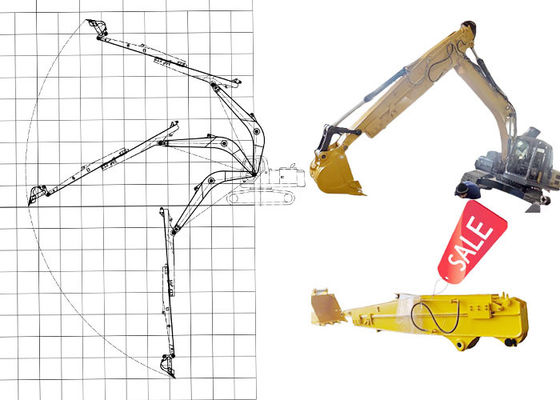

Premium Material Shaogang Q355B Excavator Pile Driving Arm Pile Driving Boom

Here is our product catalog: 2024 Zhonghe Machinery--Product Catalog.pdf

Key Advantages of Excavator Pile Driving Arm:

Lessen Maintainment: We use seamless precision steel pipe, centralized lubrication system, the boom seat sleeve adopts all in one molding process, graphite alloy copper sleeve as the material

Strong Enough: Multi-layer reinforcing rib plate at the stress place, more firm, integrated molding

Longer Life-span: reinforced upper and lower cover plates prolongs service life.

High Efficiency

Description of pile driver attachment for excavators:

In the construction work, Excavator Pile Driving Arm can carry a pile driver hammer or an auger attachment. The connectors we adopt is Ningbo connectors which is better one. Four layers five passes welding make sure that the pile driving arm has strong welding.

Specifications of one set of excavator pile driving arm:

| Excavator Model (ton) |

Section (m) |

Total Length of pile driving arm (m) |

| 20-24T |

8 |

11-12 |

| 3 |

| 25-28T |

8.5 |

12.5-13 |

| 3.5 |

| 30-38T |

9.7 |

13.5 |

| 3.8 |

| 36-39T |

10.5 |

15 |

| 4.5 |

| 40-47 |

9.8 |

13-14.2 |

| 4 |

| 40-50 |

11 |

15-15.8 |

| 4.8 |

| 45-52 |

11.5 |

16.5-16.8 |

| 5.3 |

| 47-52 |

12.2 |

18-19 |

| 6 |

| 49-52 |

14 |

21-22 |

| 7 |

| 65-85 |

15.2 |

24m |

| 8.8 |

One set of pile driving arm includes one big boom, one small arm, other accessories.

Any interest, welcome to contact. Whatsapp: 0086 13822325403

Excavator Pile Arm's details:

* Comparing with the same length pile driving arm, excavator pile driving arm can pile higher.

* The boom seat sleeve adopts all in one molding process

* Multi-layer reinforcing rib plate at the stress place, more firm, integrated molding

* Adopt 90 degree elbow joint to avoid hose bending and increase it service life

* Seamless precision steel pipe

* Centralized lubrication system

* Reinforced upper and lower cover plates prolongs service life.

* Hydraulic pipelines section design, convenient for later maintenance, lessen the maintenance cost

* Graphite alloy copper sleeve as the boom end which enhances wear resistance

Producing Details of one set of excavator pile driving arm:

* We are armed with a professional and experienced team, 24h available for answering your questions.

* The production machines we have are the most precision.

* Full & comprehensive tests are conducted during the production of excavator pile driving arm.

Fairs we attended--our excavator pile arm earned a huge market arround the world:

Welcome to contact for big discount.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!