1. Product Overview of excavator telescopic boom:

- Name of the product: excavator telescopic boom

- Suitable Excavator Brand for one set of telescopic dipper for excavator: Kato, Hitachi, Komatsu, Sany, Sumitomo, Zoomlion, etc

- Category: Construction Equipment

- Applications of one set of clamshell telescopic arm:excavation, material handling, and construction.

2. Key Features of Excavators Boom Dipper Arm:

Teledipper Arm for Excavator

The extendable arm enhances reach and depth capabilities, allowing for a maximum digging depth of 25m, 30m, 32m, or 35m with a clamshell telescopic design. It features hydraulic actuation for smooth and efficient operation.

Clamshell Bucket for Excavator Teledipper

Equipped with dual jaws, the clamshell bucket provides effective gripping and lifting. It comes in various sizes, including 0.5m³, 1m³, 1.5m³, 2m³, and 3m³, making it suitable for a wide range of materials such as soil, gravel, and debris.

Control System for Telescopic Arm with Clamshell Bucket

The advanced hydraulic control system ensures precise movements, complemented by an operator-friendly interface for ease of use.

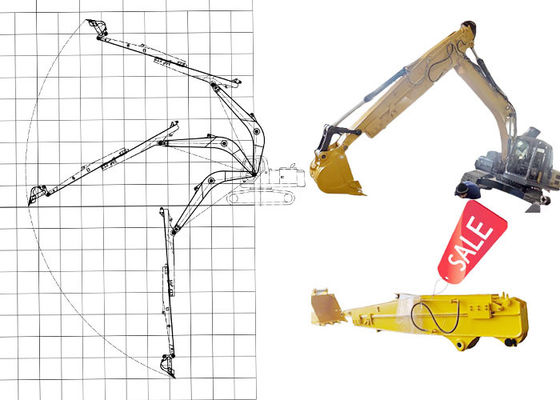

3. Technical Specifications of one set of telescopic boom excavator

* Welcome to send your excavator model to us. Suitable length of one set of telescopic arm for excavator will be sent soon.

Technicial specification of one set of 30m telescopic arm for excavator are as follow:

* Long reach *Professional *Big capacity

|

A: Maximum vertical digging depth: 30000mm

B: Maximum vertical excavation radius: 7095mm

C: Maximum vertical excavation working radius:8801mm

D: Maximum vertical digging depth: 27311mm

E: Maximum vertical excavation radius: 13586mm

F: Maximum soil unloading height: 8044mm

G: Minimum turning radius: 6150mm

H: Overall machine height at minimum turning radius: 15287mm

|

More shows of our Telescopic arm for sale:

Material we used on the excavator clamshell telescopic arm:

* High quality steel material: BS900E, lighter and stronger

-

High Strength:

- BS900E is known for its excellent tensile strength, providing the structural integrity needed to handle heavy loads and demanding conditions.

-

Durability:

- The material exhibits superior resistance to wear and fatigue, ensuring a longer lifespan for the telescopic arm even under continuous use.

-

Weldability:

- BS900E is designed for easy welding, allowing for efficient fabrication and repairs, which is crucial for maintaining the integrity of the telescopic arm.

-

Impact Resistance:

- This material can withstand sudden impacts and shocks, making it suitable for the rigorous tasks typically performed by excavators.

-

Corrosion Resistance:

- BS900E is often treated to resist corrosion, which is essential for equipment exposed to various environmental conditions, extending the arm's service life.

* High quality wire rope of excavator teledipper:

* High quality of Excavator Long Reach Boom And Telescopic Arm:

Durable Construction

Precision Engineering

Advanced Sealing Technology

Corrosion Resistance

Smooth Internal Surface

Production details of one set of excavator clamshell telescopic boom:

*High proceeding precision machine: Our telescopic arm for excavator is proceeded by Large floor-standing double-sided boring machine ensure machining precision of no less than 0.05mm

Every Plate Fully Beveled Before Welding

Purpose of Beveling the Long Boom Arm Plate

Beveling the edges of the long boom arm plate is essential for ensuring proper weld penetration. Most industrial welding machines typically achieve a penetration depth of only 3mm. Given that our long arm plate is at least 8mm thick, failing to bevel the edges would hinder effective penetration of the entire joint. This can lead to weak welds and an increased risk of cracking over time.

We utilize mechanical beveling for this process, while many other factories depend on manual beveling, as illustrated in the accompanying figure.

Certifications we have:

* More than 8 years+ experienced *Professional technicians team * Experienced staffs

Any interest, feel free to contact us:

Welcome to contact Aria--sales manager of Zhonghe Machinery.

Whatsapp: wa.me/+8613822325403

Email: aria@excavatorboomarm.com

13822325403@163.com

Website link: www.excavatorlongarm.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!