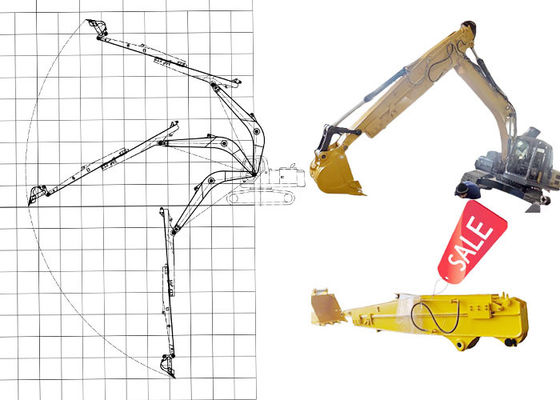

Excavator Telescopic Arm Q355B High Efficiency in Construction Work

Note: There are more than 400+ clients who chose our excavator dipper arm sliding arm. More than 900 sets telescopic boom excavator are sold every year. The good feedback is up to 99%.

Brief introduction of our telescopic boom excavator:

* High efficiency. The loading cycle down and up: 15 seconds

* Lower fail rate: The easy to wear parts can be changed once a year. The tube, cylinder, high pressure hoses are all enhanced which ensure longer service life-span.

* Easy maintenance: Just need to add lubricant regularly.

Introduction of one set of Our excavator telescopic arm with bucket:

*Relyed on a long cylinder to extend and retract the arm *Deeper digging depth than standard arm and standard boom

*Smaller Swing Range *With longer service life-span than other suppliers

Telescopic Arm for Excavator is Suitable for Various Excavator Brands:

* Hitachi *Komatsu *Sany *Zoomlion etc

Installation and feedback of one set of excavator telescopic arm from clients:

* The original breaker pipeline control telescopic arm for excavator's the long cylinder

* The original bucket cylinder control telescopic arm for excavator's bucket cylinder

Key words: Easy install

Specifications of Our telescopic arm for excavator:

|

Excavator Model

(Ton)

|

Effective Length

(mm)

|

Max Depth

(mm)

|

Max Radius

(mm)

|

Bucket Capacity

(cbm)

|

| 12-15T |

5700 |

8000 |

10400 |

0.2-0.3 |

| 20-25T |

9150 |

10000 |

13000 |

0.4-0.7 |

| 20-25T |

11000 |

12000 |

15200 |

0.4-0.7 |

| 30-35T |

11000 |

12000 |

15800 |

0.6-0.9 |

| 40-45T |

12100 |

16000 |

19200 |

0.8-1.3 |

*Special Design * Full Tests *Longer Service Life-span * High working efficiency

Details of one set of telescopic arm for excavator:

Production Details of telescopic arm for excavator:

* High precision production machines: ① Large Floor-Standing Double-Sided Boring and Milling Lathe

* Standard production line: from materials to design, every steps are full modeled and tested before production.

* Strict tests and supervision: ① weld flaw detection ②assemble test ③regular test

* More than 8 years experience

What's the purpose of steel beveling before welding?

Beveling prior to welding is essential for shaping the edges of metal surfaces into a sloped form, which promotes deeper penetration of the weld joint. This technique significantly boosts the strength and durability of the weld by enabling a more complete fusion of the materials, thereby minimizing the chances of flaws like cracks or insufficient welds. Furthermore, beveling contributes to the formation of a consistent weld bead and enhances the aesthetic quality of the final product. Proper edge preparation through beveling ensures a more effective and long-lasting welding process.

What's the purpose of processing by large double boring machine?

The primary goal of utilizing a large double boring machine is to ensure precise and efficient machining of sizeable workpieces, especially in scenarios where accurate hole placement and alignment are crucial. This machine's dual-sided functionality enables concurrent boring operations, which considerably shortens cycle times and boosts productivity. By leveraging cutting-edge technology, it guarantees consistent quality and dimensional accuracy, making it particularly suitable for demanding sectors like aerospace, automotive, and construction. In summary, the large double boring machine optimizes manufacturing workflows while upholding rigorous standards of precision.

What's the purpose of weld flaw detection of every welding?

The aim of weld flaw detection is to identify and evaluate imperfections or defects in welded joints that may jeopardize structural integrity and safety. Utilizing several non-destructive testing techniques, including ultrasonic, radiographic, and magnetic particle inspections, this process ensures that problems—such as cracks, voids, or incomplete fusion—are recognized promptly. This is vital for upholding rigorous quality standards in construction and manufacturing, ultimately averting failures that could result in expensive repairs, accidents, or safety risks.

Certifications of Our telescopic arm for excavator:

Feedback from Clients Who Chose Our telescopic arm for excavator:

Contact Us:

Kaiping Zhonghe Machinery is a big Manufacturer of Excavator Arms and Booms

Key word: long reach boom excavator, pile arm pile boom, demolition arm, shorten arm/ tunnel arm, rock arm rock boom, telescopic arm, etc

Welcome to contact for a big discount!

Whatsapp: +86 13822325403

Email: aria@excavatorboomarm.com

13822325403@163.com

Website link: www.excavatorlongarm.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!