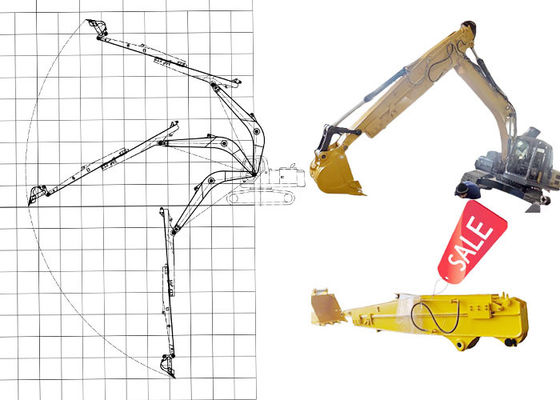

Telescopic Dipper Arm with Clamshell Bucket / Grapple 25m 28m 30m 32m

Introduction of one set of Kaiping Zhonghe Machinery's excavator telescopic boom arm:

The Kaiping Zhonghe Machinery's excavator telescopic boom arm represents a remarkable achievement in engineering design, seamlessly blending functionality with innovation. Excavator telescopic arm is engineered to enhance the versatility and reach of excavators, allowing for efficient operation in a variety of challenging environments. With its robust construction and lightweight materials, the design of excavator telescopic arm minimizes wear while maximizing performance. The telescopic feature enables operators to adjust the arm length easily, providing enhanced maneuverability and precision in tasks such as digging, lifting, and material handling. Excavator telescopic arm boom exemplifies Kaiping Zhonghe's commitment to quality and excellence in machinery design, ensuring that users achieve optimal productivity and operational efficiency.

Suitable working environment of excavator telescopic boom arm:

* Construction Sites: Ideal for urban construction projects where space is limited, allowing for precise digging and lifting in confined areas.

Specifications of one set of excavator telescopic arm:

One set of telescopic boom arm with clamshell bucket include: one telescopic arm, one clamshell bucket, pins, high pressure hose.

| Digging Depth(m) |

Excavator Model(ton) |

Bucket Capacity of Clamshell Bucket(cbm) |

Counterweight(ton) |

| 10 |

10-15T |

0.2 |

0.6T |

| 12 |

0.2 |

1T |

| 12 |

20-25T |

0.6 |

0 |

| 14 |

0.4 |

0 |

| 16 |

0.4 |

0 |

| 18 |

0.4 |

2 |

| 20 |

26-28 |

0.6 |

3 |

| 20-22m |

30-33T |

1.5cbm |

0 |

| 35-38T |

| 25m |

30-33T |

3T |

| 35-38T |

0 |

| 35-38T |

2.2cbm |

6T |

| 40-50T |

0 |

| 26-30m |

36-50T |

1.5cbm |

5T |

| 1.5cbm |

| 2cbm |

6T |

| 2cbm |

| 2.2cbm |

7T |

| 2.2cbm |

| 40-50T |

2.2cbm |

6T |

| 31-32m |

40-50T |

2.2cbm |

7.2T |

| 2.5cbm |

7.2T |

Front attachments of one set of excavator telescopic arm:

* Clamshell Bucket *Bucket Grapple

Production Details of one set of excavator telescopic arm:

* Material Selection of one set of telescopic excavator: High-Strength Steel: Utilized for its durability and resistance to wear and tear, ensuring longevity under heavy loads.

* Design and Engineering:

CAD Modeling: Advanced computer-aided design tools are employed to create precise models, allowing for thorough testing and optimization of the structure.

Stress Analysis: Finite element analysis (FEA) is performed to identify potential weak points and ensure the arm can withstand operational stresses.

Manufacturing Process:

CNC Machining: Precision machining techniques are used to manufacture components with exact specifications, ensuring high quality and consistency.

Welding: Robotic and manual welding methods are applied for robust joints, enhancing structural integrity.

Assembly:

Modular Construction: Components are assembled in modules to facilitate easier handling and maintenance, allowing for quick assembly and disassembly.

Quality Control: Each unit undergoes rigorous inspection and testing to ensure it meets industry standards and performance criteria.

Painting: Finishing paint is applied for aesthetic appeal and additional protection against environmental factors.

Testing:

Load Testing: Each boom arm is subjected to load testing to confirm its operational capacity and safety under expected working conditions.

Functional Testing: Comprehensive testing is conducted to ensure smooth telescoping action and overall functionality before delivery.

Packaging and Delivery:

Secure Packaging: Each unit is carefully packaged to prevent damage during transit, utilizing custom crating and cushioning materials.

Logistics Coordination: Efficient logistics management ensures timely delivery to clients, facilitating smooth project initiation.

These production details highlight the meticulous approach taken to create a high-quality excavator telescopic boom arm that meets the demands of various industries.

Main Equipments of Production Line

Production Line

* Every procedure of production of excavator telescopic arm is under strict control.

* Every procedure of production of telescopic arm excavator is strict proceeded.

Details of one set of excavator telescopic arm:

1. Material of one set of telescopic excavator: the material of the tube is BS900E. lighter, stronger, longer life-span.

2. Pulley of one set of excavator telescopic arm dipper stick 28m: The pulley is made of MC steel, which has the same hardness as steel, but is light and wear-resistant. The wheel diameter is enlarged to withstand greater loads.

3. Bearings of one set of excavator telescopic boom arm: The bearings are high-speed heavy-load bearings, and the bearings use larger diameters to withstand greater loads.

4. Wire rope of one set of telescopic dipper for excavator: using multi-strand wire rope can bear greater tension and impact force.

5. Excellent design of one set of clamshell telescopic arm excavator: Very few failures, and later maintenance is more convenient.

6. Production process of one set of excavator telescopic boom arm: Using better welding wire and better processing technology ensure the accuracy of the arm tube.

7. Excavator Telescopic boom is our mature product. Positive feedback.

Engineering Cases of excavator telescopic arm:

The feedback from clients is very positive.

Introduction of Kaiping Zhonghe Machinery Company:

* Professional *Experienced * 24 Hours Available

Contact Details:

Kaiping Zhonghe Machinery is a big Manufacturer of Excavator Arms and Booms

Key word: long reach boom excavator, pile arm pile boom, demolition arm, shorten arm/ tunnel arm, rock arm rock boom, telescopic arm, etc

Welcome to contact for a big discount!

Whatsapp: +86 13822325403

Email: aria@excavatorboomarm.com

13822325403@163.com

Website link: www.excavatorlongarm.com

manufacturer excavatorlongarm longreachboomexcavator excavator excavation excavatorshortenarm excavatorshortenboom tunnel tunnelarm tunnelboom

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!