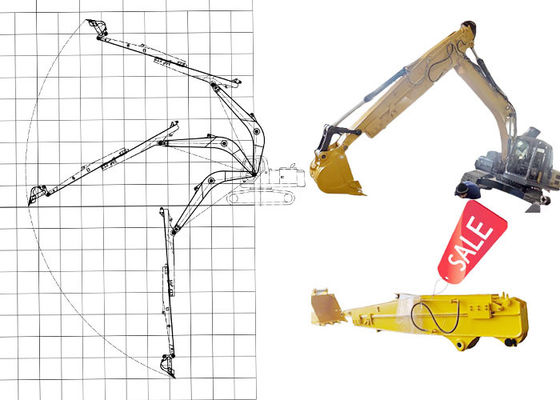

An excavator telescopic arm consists of a rigid main body, a sliding extension, a steel rope, and a hydraulic telescoping mechanism. Changing the number of sliding sections enables a customizable digging range and depth. When combined with a bucket, it facilitates deep excavation work for materials such as soil, sand, and coal.

The two-section boom is engineered using LG700 steel for high strength, while Q355B offers additional support for a lightweight build. Key characteristics:

-

22-ton bucket cylinder for superior performance

-

Enlarged spring plates in the reel system

-

Reinforced multi-layer bearings

-

LG700 steel box frame for optimal strength

-

Strengthened pivot point to withstand heavy excavation forces

High precision machine of Zhonghe Machinery Manufacturers

Large, floor-mounted double-sided boring and milling lathe:

- Increased Precision and Consistency: The double-sided boring and milling lathe enhances operational accuracy and consistency.

- Post-Welding Process: After welding, the machine bores through the hole, ensuring the parallelism and verticality of the shaft.

- Main Responsibility: This machine is primarily used for post-welding boring of large and small arms and buckets to ensure accuracy.

- Simultaneous Boring: The double-sided boring lathe performs boring on both sides at the same time, guaranteeing even accuracy.

About Zhonghe Machinery Company Profile:

Since 2018, Kaiping Zhonghe Machinery Co., Ltd. has been a reliable manufacturer of custom excavator boom arms and attachments. Operating from a 21,000m³ high-tech workshop in Kaiping, Guangdong, we leverage state-of-the-art machinery and an experienced workforce of 100+ experts, including 50 skilled welders, 30 senior engineers, and an R&D team with 10+ years of industry expertise and 100+ patents. Through strict production standards, cost-effective solutions, and a commitment to excellence, we produce up to 800 boom arms annually, serving a global market with high-quality products.

CE certification & Utility model patent certificates

Our products have been sold to more than 60 countries, and our transportation methods include sea transportation, land transportation, and air transportation. Our packaging is wooden box packaging or stretch film packaging. The goods will be packed before shipment and then loaded into the container to ensure the safety of the goods.

Packaging & Shipping

FAQ(Some frequently asked questions):

Q: Are you a manufacturer?

A: Zhonghe machinery offered a wide range of attachment parts for excavators and dozers. Such as long reach arm, demolition arm, telescopic arm, standard bucket, rock bucket, cleaning bucket, tilting bucket, etc. We know that the perfect combination of high-quality cast steel products and a moderate price is the key to the success.

Q: Is the length of the telescopic arm the total length or the digging depth?

A: The length of a two-stage telescopic arm refers to the digging depth. For example, a 14-meter telescopic arm means that the maximum digging depth is 14 meters, so it is called a 14-meter telescopic arm. The actual arm length is not only 14 meters.

Q: What material is the telescopic arm made of?

A: The arm tube of the telescopic arm is made of a690 or HG785 material, and the material of other parts is a355B material.

Q: What are your terms of payment?

A: We prefer T/T (50/50) through Ali Credit Insurance as a trial order.

Q: Are you always delivered on time?

A: We can't promise about the sea freight but what we can do is shorten our lead time while keeping the same quality level. So there will not be any problem even if the sea freight is delayed for a couple of days.

More details, contact Ada!!!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!