| |

Rock Boom Seperate-arm Ripper |

Rock Boom Mono-arm Ripper |

| In weight |

A 50-ton excavator weighs 21-22 tons |

A 50-ton excavator weighs 17.5-19 tons |

| In appearance |

The boom cylinder is no different from the standard boom cylinder, with single oil inlet and single oil return. |

The arm and the ripper are integrated into one design, a one-piece style. |

| In stick cylinder |

The boom cylinder is no different from the standard boom cylinder, with single oil inlet and single oil return. |

The arm cylinder has double oil inlet and double oil return (it integrates the oil inlet and oil return of the bucket cylinder into the arm cylinder). |

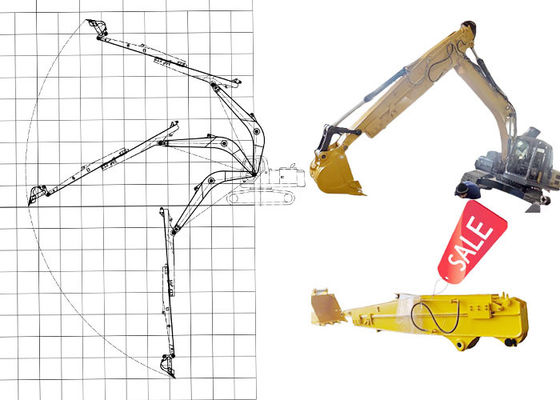

General Arrangement Drawing

Suitable Working Conditions for Excavator Rock Arms:

Heavy Rock and Boulders in Waterlogged Areas

Excavator rock arms are effective in waterlogged areas where boulders and heavy rock need to be removed, such as riverbeds or marshy areas. The strength of the boom, combined with an appropriate ripper attachment, allows for effective digging and rock breaking in muddy or water-saturated soils. This is particularly useful in river excavation or clearing waterlogged land for construction projects.

- Key features for waterlogged areas: Hydraulic systems designed for underwater use, rust-resistant components.

- Common use cases: Riverbed excavation, removing boulders from marshy or flooded land, dredging operations.

High precision machine of Zhonghe Machinery Manufacturers

Large, floor-mounted double-sided boring and milling lathe:

- Improved Operational Precision and Consistency: This machine enhances both the precision and consistency of the operations.

- Post-Welding Process: After welding is finished, it bores the hole to ensure the shaft’s parallelism and verticality.

- Main Usage: The machine is primarily responsible for post-welding boring of large and small arms and buckets to ensure the accuracy of the arm.

- Dual-Side Boring: The double-sided boring lathe performs boring on both sides simultaneously, ensuring consistent precision.

About Zhonghe Machinery Company Profile:

Kaiping Zhonghe Machinery Co.,Ltd. established in 2018, it is a combination of manufacturing and trading, specializing in customizing different kinds of excavator boom arms and attachments. We are located in cuishanhu New District. Kaiping cityJiangmen City. Guangdong Province, China. We boast a 21000m3 steel structure workshop with a large number of high precision processing equipment and a strong and cohesive team of over 100 experienced technical staff. 50 welding workers with over 7 years experience. 30 senior designers, and a high-tech R&D team(10+ years on customization.100+technical patents), strict production system(6+ years quality control and cost control) and warm-hearted service team. Our annual output of various types of excavator boom arms can reach up to 800 sets.

CE certification & Utility model patent certificates

Our products have been sold to more than 60 countries, and our transportation methods include sea transportation, land transportation, and air transportation. Our packaging is wooden box packaging or stretch film packaging. The goods will be packed before shipment and then loaded into the container to ensure the safety of the goods.

Packaging & Shipping

FAQ(Some frequently asked questions):

Q:What are the configurations of the rock arm?

A:1. Split rock arm configuration: one set of large and small arms, one arm cylinder, one bucket cylinder, one ripper, four high-pressure hoses, and seven pins.

2. Integrated rock arm configuration: one set of large and small arms, four pins, four high-pressure hoses, and one arm cylinder

Q:How long does it usually take to produce a rock arm?

A:After the customer pays a 30% deposit, it usually takes 20-35 days to complete. We can deliver on time.

Q: Are you a factory?

Yes, we are a factory, we are in Kaiping City, Guangdong Province. We have a large factory with complete production equipment. There is also a large double-sided floor boring machine, which can produce rock arms and ensure that the rock arms are bored accurately with almost no error. Customers are welcome to visit our factory at any time

Q: What are your terms of payment?

A: We prefer T/T (50/50) through Ali Credit Insurance as a trial order.

Q: Are you always delivered on time?

A: We can't promise about the sea freight but what we can do is shorten our lead time while keeping the same quality level. So there will not be any problem even if the sea freight is delayed for a couple of days.

Any information, pls contact

Whatsapp: +86 18127591702

Wechat/Tel: 0086 18127591702

E-mail: sophia@excavatorboomarm.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!