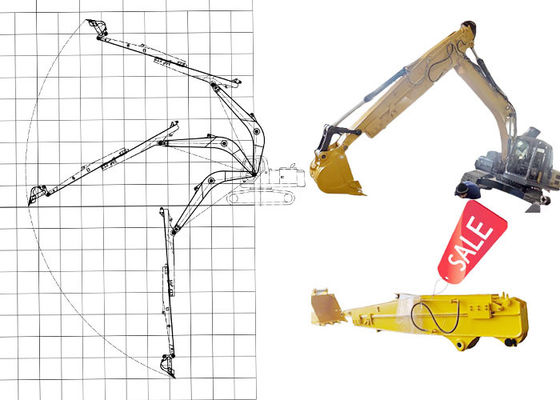

Telescopic Dipper Arm External Telescopic Boom Excavator Sliding Arm Attachment for Heavy Machinery Long Reach Boom

Telescopic boom/Sliding Arm Details

1. The sliding arm is used to dig deep wells, foundation pits, tunnels, sewage pipelines and other municipalities.

2. Our company was established in 2018 and has more than 6 years of experience. The production line engineers have more than 10 years of data and experience to design and customize long arms for excavators of various brands.

3. Suitable for all excavator models, OEM services are also provided.

4. Advanced manufacturing process, technology meets global standards.

5. We have all the installation dimensions for most excavators, and we can customize this long arm for your excavator.

6. Before welding, we use a large milling machine to mill (taper processing) the edge of the steel plate. Therefore, the welding can enter the inside of the steel plate, giving the structure higher performance. And there are reinforcement plates inside to make it stronger.

7. If necessary, additional pipes can be added to accommodate some additional applications.

8. The arm cylinder of the long boom, you can use your original arm cylinder to save costs, if you need an arm cylinder, we can also prepare it for you.

9. Some parts can be reinforced with thicker plates or overlap another plate for heavy-duty applications.

10. Welding is shielded gas welding, the shielding gas is a mixture of 80% argon and 20% carbon dioxide. This is the gold standard of shielding gas.

11. Before welding, we use a large milling machine to mill the edge of the plate. So the welding can go inside the steel plate, making the structure have higher performance.

12. We can customize the arm for various excavators according to your requirements. Just tell me your requirements.

13. If you need, some parts can be reinforced with thicker plates or overlap another plate for heavy-duty applications, just tell me.

EXCAVATORS WITH A TELESCOPIC ARM

EXCAVATORS WITH A TELESCOPIC ARM

(UPPER ARM SLIDING TYPE)

1. Thanks to the hydraulic sliding system in this model, the arm contracts and expands (‘telescopes’) speedily, providing high working efficiency.

2. Sliding mechanisms using rollers on the slide surfaces makes adjustment easy and prevents vertical and horizontal vibrations of the arm, which in turn minimises the wear which shortens arm life.

3. With the arm extended, the excavator can dig to the same depth as machines three (3) classes higher, so this becomes a useful attachment for restricted job sites where a wide working range is needed.

4. In addition, slope-finishing work can also be done with ease.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Some size references

|

Excavatoe

(Ton)

|

Effective Length

(mm)

|

Max Depth

(mm)

|

Max Radius

(mm)

|

Bucket Capacity

(cbm)

|

| 12-15T |

5700 |

8000 |

10400 |

0.2-0.3 |

| 20-25T |

9150 |

10000 |

13000 |

0.4-0.7 |

| 20-25T |

11000 |

12000 |

15200 |

0.4-0.7 |

| 30-35T |

11000 |

12000 |

15800 |

0.6-0.9 |

| 40-45T |

12100 |

16000 |

19200 |

0.8-1.3 |

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Product Details of Telescopic Arm

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

What is the purpose of beveling the long arm/tunnel arm plate?

Most welding machines commonly used in the industry have a penetration depth of only 3mm. Since the thickness of our long arm plate is at least 8mm, without beveling, the welder would not be able to fully penetrate through the entire joint. This would result in weak welds, leading to issues such as weld cracking in the future.

We employ mechanical beveling, whereas other factories rely on manual beveling (as shown in the figure).

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

High precision machine of Zhonghe Machinery Manufacturers

Large Floor-Standing Double-Sided Boring and Milling Lathe:

- Improved Accuracy and Consistency: The double-sided boring and milling lathe enhances the precision and uniformity of operations, ensuring consistent results.

- Post-Welding Processing: After the welding process, the machine performs overall boring, ensuring the parallelism and perpendicularity of shaft holes.

- Primary Applications: Primarily used for post-weld boring of the boom, small arm, and bucket, ensuring the accuracy and proper alignment of the boom.

- Simultaneous Boring on Both Sides: The lathe performs boring on both sides at the same time, guaranteeing identical precision and consistency on both sides.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

About Zhonghe Machinery Company Profile:

Kaiping Zhonghe Machinery Manufacturing Co., Ltd.

1. Founding Year: Kaiping Zhonghe Machinery Co., Ltd. was launched in 2018.

2. Specialization: We focus on manufacturing and trading customized excavator booms and accessories.

3. Location Details: Our facility is in Cuishan Lake New District, Kaiping City, Jiangmen, Guangdong Province, China.

4. Workshop Size: We maintain a 21,000 m³ steel structure workshop equipped for production.

5. Machinery Details: Our workshop features advanced high-precision processing machinery.

6. Team Composition: Our workforce includes over 100 technicians, comprising:

- 50 welders with over 7 years of experience.

- 30 senior designers.

7. Innovation and R&D: Our R&D team has over 10 years of experience and holds over 100 technical patents.

8. Production System: We implement a strict quality control system, developed over 6 years for cost management.

9. Production Capacity: We can produce up to 800 sets of different types of excavator booms each year.

10. Customer Service: We prioritize quality and customer satisfaction, encouraging global partnerships.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

CE certification & Utility model patent certificates

Our products have been exported to over 60 countries, utilizing various transportation methods such as sea, land, and air freight. For packaging, we use either wooden crates or stretch film to secure the products. Before shipment, the goods are carefully packaged and then loaded into containers to ensure their safety during transit.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Packaging & Shipping

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

FAQ(Some frequently asked questions):

Q: Are you a manufacturer?

A: Zhonghe machinery offered a wide range of attachment attachments for excavators . Such as long reach arm, demolition arm, telescopic arm, standard bucket, rock bucket, cleaning bucket, tilting bucket, etc. We know that the perfect combination of high-quality cast steel products and a moderate price is the key to the success.

Q: How long is the sliding arm for a conventional 20 ton excavator machine?

A: The 9-meter sliding arm is the 10-meter sliding arm in our price list. The 9-meter sliding arm here refers to the 9-meter sliding arm that can dig to more than 8 meters or nearly 9 meters without pressing down the arm. This is what the customer calls the 9-meter sliding arm.

Q: What length does the 10-meter sliding arm in our product price list refer to?

A: This 10 meters refers to the maximum digging depth of more than 10 meters, not the actual length of the arm, but the depth of the bucket.

Q: What are the advantages of our sliding arm?

A: First, the double limit design reduces the vibration of the oil cylinder.

Second, our sliding arm adopts the wear-resistant block design instead of the pulley design, which increases the service life, reduces the failure rate, and is more convenient for maintenance.

Third, the sliding arm has strong versatility and uses more original accessories, which reduces the user's budget.

Fourth, we have the highest market share and the highest customer recognition.

Fifth, our sliding arm oil cylinders are all designed with double-layer oil seals to reduce the failure rate of the oil cylinder.

Any information, pls contact

Whatsapp: +86 18127591702

Wechat/Tel: 0086 18127591702

E-mail: sophia@excavatorboomarm.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!