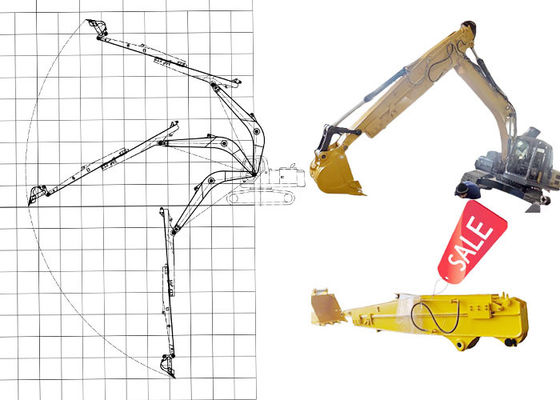

Large Floor-Standing Double-Sided Boring and Milling Lathe:

- Improved Accuracy and Consistency: The double-sided boring and milling lathe enhances the precision and uniformity of operations, ensuring consistent results.

- Post-Welding Processing: After the welding process, the machine performs overall boring, ensuring the parallelism and perpendicularity of shaft holes.

- Primary Applications: Primarily used for post-weld boring of the boom, small arm, and bucket, ensuring the accuracy and proper alignment of the boom.

- Simultaneous Boring on Both Sides: The lathe performs boring on both sides at the same time, guaranteeing identical precision and consistency on both sides.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

About Zhonghe Machinery Company Profile:

Kaiping Zhonghe Machinery Manufacturing Co., Ltd.

Kaiping Zhonghe Machinery Co., Ltd. has been operational since 2018, focusing on the customization of excavator booms and accessories. Our 21,000 m³ workshop in Jiangmen City is equipped with high-precision machinery. We have a dedicated team of over 100 technicians, including 50 welders with substantial experience, and 30 senior designers. Our R&D division, with more than 100 patents, emphasizes innovation and quality, allowing us to produce up to 800 sets annually.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

CE certification & Utility model patent certificates

Our products have been exported to over 60 countries, utilizing various transportation methods such as sea, land, and air freight. For packaging, we use either wooden crates or stretch film to secure the products. Before shipment, the goods are carefully packaged and then loaded into containers to ensure their safety during transit.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Packaging & Shipping

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

FAQ(Some frequently asked questions):

Q: Are you a manufacturer?

A: We are a manufacturer/supplier of excavator arms and attachments. We have a super large factory. The factory area is several times that of our competitors. It is the largest excavator attachment factory in Guangdong Province. It has complete production equipment and its products have been exported to more than 60 countries around the world.

Q: Why choose Zhonghe over any other companies?

A: We have a professional production team and design team to provide each customer with high-quality and personalized customer service to ensure correctness, so we have good reputation in China, and our annual sales are among the best in our country.

Q: What can I get from you?

A: 1. The product is made of Q355B steel, a superior and sturdy material on the market, and the steel is cut with a 45-degree slope and then gas welded, making it more sturdy and 30% longer lifetime than normal materials.

2. All accessories are included, no additional purchases are required. Professional online video guides installation to make installation worry-free.

3. Lifetime free online customer service consultation if you have any questions.

Q: How do I start to order?

A: Firstly, talk to our sales about your machine model, working conditions, special needs and deadline. Then our sales will give you proposals FYR. You will receive a quotation ASAP after confirming the proposal.

Q: What are your terms of payment?

A: We prefer T/T (50/50) through Ali Credit Insurance as a trial order.

Q: Are you always delivered on time?

A: We can't promise about the sea freight but what we can do is shorten our lead time while keeping the same quality level. So there will not be any problem even if the sea freight is delayed for a couple of days.

Any information, pls contact Ada!!!!

Whatsapp: +86 15322105263

Wechat/Tel: 0086 15322105263

E-mail: abby@excvatorboomarm.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!