Buy Telescopic Boom for Excavator Telescopic Arm Attachments for Sale Comparing Telescopic Boom Options for Excavators

Any information, pls contact Ada!

this is my contact way directly

Sophia W/A: +86 15322105263

Mail: ada@excavatorboomarm.com

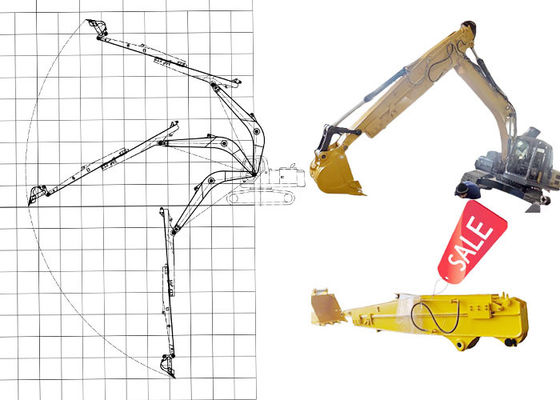

Product Description-------Excavator Telescopic Boom

What is an excavator telescopic arm?

The telescopic arm is an advanced accessory for excavators that enhances their functional capabilities. It allows for increased reach, making it easier to work in various applications, including demolition, site preparation, and infrastructure development.

What are your advantages?

Advantages of telescopic arms:

1. Constructed from BS900E and Q355B, our three-section telescopic boom is designed to be both lightweight and durable.

2. It incorporates a wall thickness of 6mm for increased strength.

The boom features nylon sliders and steel pulleys, with all hoses lubricated centrally.

3. The bucket cylinder’s external hose pulley makes it easier to replace and service hoses.

4. Separating the hose from the main rope reduces friction, minimizing potential issues.

5. With a dual-rope design, the telescopic arm ensures safety by preventing extension if the main rope breaks.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Some common size references

|

Excavator

(ton)

|

Max Depth

(mm) |

Effective Length

(mm) |

Bucket Capacity

(cbm)

|

| 6-10 |

10000 |

7600 |

0.2-0.3 |

| 11-15 |

14000 |

10500 |

0.4-0.6 |

| 20-30 |

16000 |

12500 |

0.8-1.5 |

| 30-35 |

20000 |

15500 |

1.3-1.66 |

| 30-35 |

25000 |

20500 |

1-1.4 |

| 40-45 |

25000 |

20500 |

1.8-2.5 |

| 40-45 |

30000 |

25100 |

1.4-2 |

Three Section Telescopic Arm Configuration

1. A set of telescopic arm

2. Two high-pressure hoses

3. Two pins

4. One clamshell bucket

5. One two-way foot switch

Some installation instructions for telescopic arms

Our designs allow for interchangeable use of digging buckets and grab buckets.

The first one is clamshell bucket ,usually use for Subway deep digging project .

The second one is the grab bucket , compare to the clamshell bucket , the grab bucket have power ,can grab the stone.

The last is the standard bucket , use for telescopic boom the bucket need do the special design .

Product Detail Display

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Telescopic Boom Arm Engineering Case

The telescopic arm of the excavator is suitable for the following working conditions:

- Site Development: The telescopic arm is invaluable for site development projects in constrained areas, allowing for efficient material handling.

- Subterranean Construction: It can effectively reach underground areas for construction tasks like sewer installation.

- Tall Structure Dismantling: The arm’s reach is beneficial for dismantling tall structures in urban settings.

- Excavation in Tight Spots: Its design is perfect for excavation tasks in tight spots where standard booms cannot operate.

- Utility Maintenance: The telescopic arm is used for maintenance of utilities in crowded urban environments.

- Roadway Excavation: It can efficiently excavate roadways that are surrounded by existing infrastructure.

- Demolition of High-Rise Buildings: The arm is effective for the demolition of high-rise buildings, providing the necessary reach without needing additional equipment.

- Underground Water Management: The telescopic arm can assist in water management projects that require excavation in tight underground environments.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

What is the purpose of beveling the long boom arm plate?

Most welding machines commonly used in the industry have a penetration depth of only 3mm. Since the thickness of our long arm plate is at least 8mm, without beveling, the welder would not be able to fully penetrate through the entire joint. This would result in weak welds, leading to issues such as weld cracking in the future.

We employ mechanical beveling, whereas other factories rely on manual beveling (as shown in the figure).

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

High precision machine of Zhonghe Machinery Manufacturers

Large Floor-Standing Double-Sided Boring and Milling Lathe:

- Improved Accuracy and Consistency: The double-sided boring and milling lathe enhances the precision and uniformity of operations, ensuring consistent results.

- Post-Welding Processing: After the welding process, the machine performs overall boring, ensuring the parallelism and perpendicularity of shaft holes.

- Primary Applications: Primarily used for post-weld boring of the boom, small arm, and bucket, ensuring the accuracy and proper alignment of the boom.

- Simultaneous Boring on Both Sides: The lathe performs boring on both sides at the same time, guaranteeing identical precision and consistency on both sides.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

About Zhonghe Machinery Company Profile:

Kaiping Zhonghe Machinery Manufacturing Co., Ltd.

Founded in 2018, Kaiping Zhonghe Machinery Co., Ltd. integrates both manufacturing and trade, specializing in customized excavator equipment. Our facility in Jiangmen City, Guangdong, features a 21,000 m³ steel workshop filled with state-of-the-art machinery. We employ a cohesive team of over 100 technicians and 50 welders with significant experience, supported by 30 senior designers. Our high-tech R&D team has amassed over 100 patents, enabling us to produce up to 800 sets of booms annually with strict quality control measures.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

CE certification & Utility model patent certificates

Our products have been exported to over 60 countries, utilizing various transportation methods such as sea, land, and air freight. For packaging, we use either wooden crates or stretch film to secure the products. Before shipment, the goods are carefully packaged and then loaded into containers to ensure their safety during transit.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Packaging & Shipping

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

FAQ(Some frequently asked questions):

Q: Are you a manufacturer?

A: We are a manufacturer/supplier of excavator arms and attachments. We have a super large factory. The factory area is several times that of our competitors. It is the largest excavator attachment factory in Guangdong Province. It has complete production equipment and its products have been exported to more than 60 countries around the world.

Q: Why does the telescopic arm have the difference between a shell bucket and a grab bucket?

A: Generally, shell buckets are easy to use for silt and sand, and can dig a large volume with higher efficiency. However, in general sand and stone work, shell buckets have no digging force and are limited by the opening, so the efficiency of shell buckets will be reduced. Grab buckets are more suitable for this kind of work. However, due to the overall weight of the grab bucket, the volume of the grab bucket is generally smaller than that of the shell bucket, but in work with more stones, the advantages of grab buckets are more obvious.

Q:Is it better to use a single cylinder or a double cylinder for the shell bucket equipped with a telescopic arm?

A:We always use the double cylinder design and never use the single cylinder design. It has the advantages of low failure rate, convenient maintenance, and less oil leakage. What are the disadvantages of the double cylinder? The first is that the shell bucket with a double cylinder is heavier, and the synchronization of grabbing is worse. The overall weight of a single cylinder is lower, and the synchronization is better, the grabbing efficiency is higher, but the failure rate is higher.

Q:What is the material of the telescopic arm?

A: The arm tube is made of BS900E, and other parts are made of Q3558, which is lighter and more durable. We use a thickness of 6mm.

Any information, pls contact Ada!

this is my contact way directly

Sophia W/A: +86 15322105263

Mail: ada@excavatorboomarm.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!