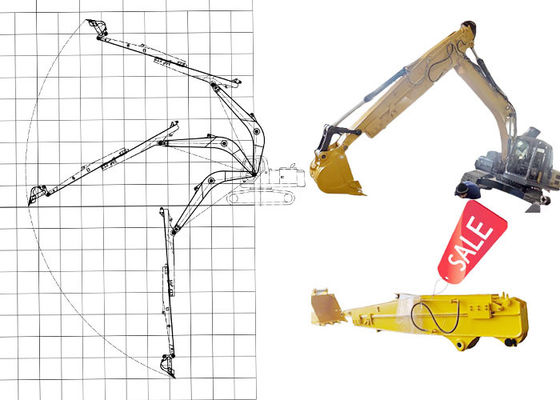

Large Floor-Standing Double-Sided Boring and Milling Lathe:

- Improved Accuracy and Consistency: The double-sided boring and milling lathe enhances the precision and uniformity of operations, ensuring consistent results.

- Post-Welding Processing: After the welding process, the machine performs overall boring, ensuring the parallelism and perpendicularity of shaft holes.

- Primary Applications: Primarily used for post-weld boring of the boom, small arm, and bucket, ensuring the accuracy and proper alignment of the boom.

- Simultaneous Boring on Both Sides: The lathe performs boring on both sides at the same time, guaranteeing identical precision and consistency on both sides.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

About Zhonghe Machinery Company Profile:

Kaiping Zhonghe Machinery Manufacturing Co., Ltd.

1. Establishment: Kaiping Zhonghe Machinery Co., Ltd. was founded in 2018.

2. Core Business: We are dedicated to manufacturing and trading customized excavator booms and accessories.

3. Location: Our facility is located in Cuishan Lake New District, Kaiping City, Jiangmen, Guangdong Province, China.

4. Workshop Dimensions: We operate a 21,000 m³ steel structure workshop designed for efficient production.

5. Machinery Use: Our workshop is equipped with cutting-edge high-precision processing tools.

6. Staff Overview: Our team consists of over 100 skilled technicians, including:

- 50 welding professionals with over 7 years of experience.

- 30 senior designers.

7. Research and Development: Our innovative R&D team has over 10 years of experience and holds more than 100 technical patents.

8. Quality Control: We implement a strict production system focusing on quality and cost control developed over 6 years.

9. Production Capability: Our facility can produce up to 800 sets of various excavator booms annually.

10. Customer Commitment: We prioritize customer satisfaction and welcome collaboration with clients from around the globe.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

CE certification & Utility model patent certificates

Our products have been exported to over 60 countries, utilizing various transportation methods such as sea, land, and air freight. For packaging, we use either wooden crates or stretch film to secure the products. Before shipment, the goods are carefully packaged and then loaded into containers to ensure their safety during transit.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Packaging & Shipping

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

FAQ(Some frequently asked questions):

Q: Are you a manufacturer?

A: We are a manufacturer/supplier of excavator arms and attachments. We have a super large factory. The factory area is several times that of our competitors. It is the largest excavator attachment factory in Guangdong Province. It has complete production equipment and its products have been exported to more than 60 countries around the world.

Q: Why does the telescopic arm have the difference between a shell bucket and a grab bucket?

A: Generally, shell buckets are easy to use for silt and sand, and can dig a large volume with higher efficiency. However, in general sand and stone work, shell buckets have no digging force and are limited by the opening, so the efficiency of shell buckets will be reduced. Grab buckets are more suitable for this kind of work. However, due to the overall weight of the grab bucket, the volume of the grab bucket is generally smaller than that of the shell bucket, but in work with more stones, the advantages of grab buckets are more obvious.

Q:Is it better to use a single cylinder or a double cylinder for the shell bucket equipped with a telescopic arm?

A:We always use the double cylinder design and never use the single cylinder design. It has the advantages of low failure rate, convenient maintenance, and less oil leakage. What are the disadvantages of the double cylinder? The first is that the shell bucket with a double cylinder is heavier, and the synchronization of grabbing is worse. The overall weight of a single cylinder is lower, and the synchronization is better, the grabbing efficiency is higher, but the failure rate is higher.

Q:What is the material of the telescopic arm?

A: The arm tube is made of BS900E, and other parts are made of Q3558, which is lighter and more durable. We use a thickness of 6mm.

Any information, pls contact Sophia!

this is my contact way directly

Sophia W/A: +86 18127591702

Mail: sophia@excavatorboomarm.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!