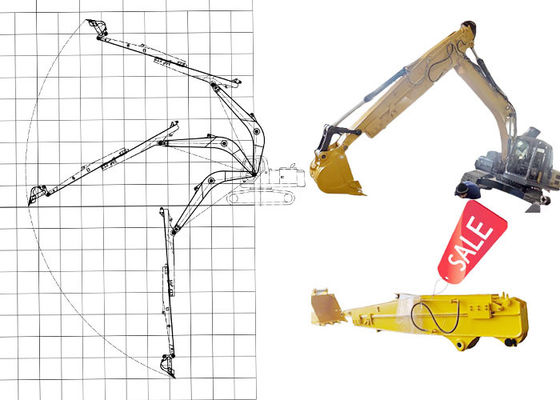

Large Floor-Standing Double-Sided Boring and Milling Lathe:

- Improved Accuracy and Consistency: The double-sided boring and milling lathe enhances the precision and uniformity of operations, ensuring consistent results.

- Post-Welding Processing: After the welding process, the machine performs overall boring, ensuring the parallelism and perpendicularity of shaft holes.

- Primary Applications: Primarily used for post-weld boring of the boom, small arm, and bucket, ensuring the accuracy and proper alignment of the boom.

- Simultaneous Boring on Both Sides: The lathe performs boring on both sides at the same time, guaranteeing identical precision and consistency on both sides.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

About Zhonghe Machinery Company Profile:

Kaiping Zhonghe Machinery Manufacturing Co., Ltd.

Established in 2018, Kaiping Zhonghe Machinery Manufacturing Co., Ltd. specializes in production and trade. We focus on customizing excavator attachments, such as long arms and buckets, with a strong presence in over 60 countries.

Key advantages are:

- A facility of approximately 18,000 square meters.

- A dedicated team of 120 employees.

- State-of-the-art equipment, including CNC cutting machines.

- A dedicated production line for custom-made solutions.

- Fast lead times, typically between 7 and 25 days.

- An annual output of 600 sets of excavator booms. Our commitment is to "Quality, Sincerity, and Customer Satisfaction," and we invite collaboration with partners globally.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

CE certification & Utility model patent certificates

Our products have been exported to over 60 countries, utilizing various transportation methods such as sea, land, and air freight. For packaging, we use either wooden crates or stretch film to secure the products. Before shipment, the goods are carefully packaged and then loaded into containers to ensure their safety during transit.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Packaging & Shipping

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

FAQ(Some frequently asked questions):

Q1: Are you a manufacturer?

A1: Zhonghe Machinery provides a wide variety of attachments for excavators. Such as long arms, demolition arms, telescopic arms, standard buckets, rock buckets, cleaning buckets, tilt buckets, etc. We know that the perfect combination of high-quality cast steel products and moderate prices is the key to success.

Q2: Why is it called a tunnel arm?

A2: Tunnel arms generally refer to working devices that operate in narrow spaces. Most of them operate in tunnels, so they are called tunnel arms. Each country has a different name, but in China we call it a tunnel arm.

Q3: What are the configurations of the tunnel arm?

A3: Depending on the height of the tunnel, the configuration that requires or does not require the boom cylinder can be designed, but the necessary configurations are: one boom cylinder, one bucket cylinder, 8 pins, 6 high-pressure hoses, one set of connecting rod assemblies, one set of crushing pipes, and 2 stop valves. The general operating height of the tunnel arm is 4-6 meters.

Q4: What are the requirements for the tunnel arm?

A4: A. It is recommended that the tunnel arm be equipped with a straight hammer. The basement height is limited. During operation, the triangular hammer part is higher than the arm plane, which will scrape the top and make the operation inconvenient. The straight hammer will not have this problem. B. The tunnel arm design does not take into account the transportation height. Generally, the transportation of large-scale mechanical tunnel arms requires the breaker to be removed before transportation. Filling materials in the forearm of the tunneling arm increases the weight of the tunneling arm, presses down the breaker, reduces the rebound force of the breaker, and increases the crushing force.

Any information, pls contact Ada!

this is my contact way directly

Ada W/A: +86 15322105263

Mail: ada@excavatorboomarm.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!