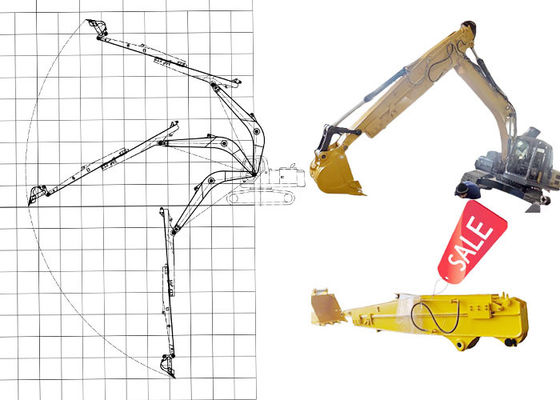

High-Performance Excavator Tunnel Arm for Urban Tunneling Short Arm Excavator Compact Excavator Boom Short Reach Arm

I. Advantages of Excavator Tunnel Arm/Short Arm

-

Optimized for Tight Spaces

- The compact design of tunnel or short arms allows for efficient operation in confined areas such as tunnels, basements, or narrow excavation sites where longer arms are impractical.

-

Enhanced Maneuverability

- Short arms offer improved agility and control, making it easier to navigate and perform precise tasks in restricted environments.

-

Minimized Risk of Collisions

- The shorter reach reduces the likelihood of the arm hitting surrounding structures or overhead obstacles, thus preventing potential damage and operational interruptions.

-

Increased Stability

- Short arms provide greater stability due to a lower center of gravity, which helps in handling heavy loads more effectively and safely.

-

Concentrated Force Application

- With a shorter arm, the force applied during operations is more concentrated, allowing the use of larger attachments like breakers or buckets for more effective impact.

-

Simplified Maintenance and Transport

- The compact size of short arms makes them easier to maintain and transport, reducing the need for disassembly and streamlining logistics.

-

Specialized Performance

- Tunnel arms are designed specifically for tasks that require precision in confined spaces, making them ideal for specialized projects.

-

Reduced Wear and Tear

- Operating in constrained environments helps minimize excessive wear and tear on the machinery, potentially extending its service life.

-

Cost Efficiency

- Generally, short arms or tunnel arms can be more cost-effective to operate and maintain due to their simpler design and reduced operational complexity.

Advantages of Zhonghe Machinery

Advantages of Zhonghe Machinery

1. Professional product design team, rich experience, strong design pertinence.

2. Automated processing equipment. Automatic cutting, double-sided floor-standing large boring machine, etc.

3. Industry standard welding process, carbon dioxide shielded welding, good weld crack resistance.

4. Strict and meticulous quality inspection, ultrasonic flaw detection

| excavator(ton) |

total length

(mm)

|

boom(mm) |

arm(mm) |

max height

(mm)

|

max depth(mm) |

| 20-25T |

1300 |

3200 |

1900 |

4500 |

8500 |

| 30-36T |

4200 |

4200 |

1900 |

5000 |

10500 |

| 40-45T |

4500 |

4500 |

1900 |

5000 |

11000 |

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Working scene of tunnel arm

Special design----meet customer needs !!!

Special design----meet customer needs !!!

What are the advantages of modifying the tunnel arm?

1. The operating range adapts to the working conditions, and there is no need to worry about the boom hitting the beams of the tunnel or basement.

2. After the tunnel boom is modified, a larger breaker can be used due to the shortening of the boom. For example, the PC120 excavator can carry a 135 breaker after modification, and the PC200 excavator can use a 165 breaker, but it is necessary to increase the confluence of double pumps, and the impact force is doubled.

3. The tunnel boom can carry a bucket. The shorter the boom, the shorter the torque, the greater the force, and the larger the bucket can be.

4. When the bucket replaces the breaker, the stop valve prevents oil leakage.

5. The pipe joints are multi-layer welded to reduce the risk of oil leakage.

6. The cylinder guard is conducive to preventing the cylinder from being damaged in a collision.

7. Factory price, cheap price, support customization, ODM or OEM service.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

|| Excavator Tunnel Arms Suitable For Application

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

What is the purpose of beveling the long arm/tunnel arm plate?

Most welding machines commonly used in the industry have a penetration depth of only 3mm. Since the thickness of our long arm plate is at least 8mm, without beveling, the welder would not be able to fully penetrate through the entire joint. This would result in weak welds, leading to issues such as weld cracking in the future.

We employ mechanical beveling, whereas other factories rely on manual beveling (as shown in the figure).

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

High precision machine of Zhonghe Machinery Manufacturers

Large Floor-Standing Double-Sided Boring and Milling Lathe:

- Improved Accuracy and Consistency: The double-sided boring and milling lathe enhances the precision and uniformity of operations, ensuring consistent results.

- Post-Welding Processing: After the welding process, the machine performs overall boring, ensuring the parallelism and perpendicularity of shaft holes.

- Primary Applications: Primarily used for post-weld boring of the boom, small arm, and bucket, ensuring the accuracy and proper alignment of the boom.

- Simultaneous Boring on Both Sides: The lathe performs boring on both sides at the same time, guaranteeing identical precision and consistency on both sides.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

About Zhonghe Machinery Company Profile:

Kaiping Zhonghe Machinery Manufacturing Co., Ltd.

Kaiping Zhonghe Machinery Co.,Ltd. established in 2018, it is a combination of manufacturing and trading, specializing in customizing different kinds of excavator boom arms and attachments. We are located in cuishanhu New District. Kaiping cityJiangmen City. Guangdong Province, China. We boast a 21000m3 steel structure workshop with a large number of high precision processing equipment and a strong and cohesive team of over 100 experienced technical staff. 50 welding workers with over 7 years experience. 30 senior designers, and a high-tech R&D team(10+ years on customization.100+technical patents), strict production system(6+ years quality control and cost control) and warm-hearted service team. Our annual output of various types of excavator boom arms can reach up to 800 sets.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

CE certification & Utility model patent certificates

Our products have been exported to over 60 countries, utilizing various transportation methods such as sea, land, and air freight. For packaging, we use either wooden crates or stretch film to secure the products. Before shipment, the goods are carefully packaged and then loaded into containers to ensure their safety during transit.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Packaging & Shipping

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

FAQ(Some frequently asked questions):

Q1: Are you a manufacturer?

A1: Zhonghe Machinery provides a wide variety of attachments for excavators. Such as long arms, demolition arms, telescopic arms, standard buckets, rock buckets, cleaning buckets, tilt buckets, etc. We know that the perfect combination of high-quality cast steel products and moderate prices is the key to success.

Q2: Why is it called a tunnel arm?

A2: Tunnel arms generally refer to working devices that operate in narrow spaces. Most of them operate in tunnels, so they are called tunnel arms. Each country has a different name, but in China we call it a tunnel arm.

Q3: What are the configurations of the tunnel arm?

A3: Depending on the height of the tunnel, the configuration that requires or does not require the boom cylinder can be designed, but the necessary configurations are: one boom cylinder, one bucket cylinder, 8 pins, 6 high-pressure hoses, one set of connecting rod assemblies, one set of crushing pipes, and 2 stop valves. The general operating height of the tunnel arm is 4-6 meters.

Q4: What are the requirements for the tunnel arm?

A4: A. It is recommended that the tunnel arm be equipped with a straight hammer. The basement height is limited. During operation, the triangular hammer part is higher than the arm plane, which will scrape the top and make the operation inconvenient. The straight hammer will not have this problem. B. The tunnel arm design does not take into account the transportation height. Generally, the transportation of large-scale mechanical tunnel arms requires the breaker to be removed before transportation. Filling materials in the forearm of the tunneling arm increases the weight of the tunneling arm, presses down the breaker, reduces the rebound force of the breaker, and increases the crushing force.

Any information, pls contact Sophia!

this is my contact way directly

Sophia W/A: +86 18127591702

Mail: sophia@excavatorboomarm.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!