Custom Demolition Arm for Excavators 10.Multi-Functional Excavator Boom with Hydraulic Shear Breaker Long Arm

Product Description-----Excavator Demolition Boom

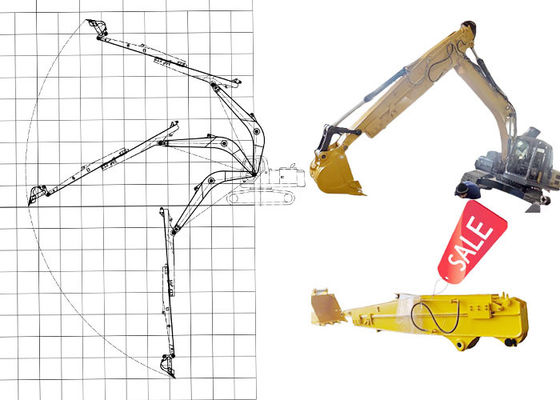

What is an excavator demolition boom arm?

An excavator demolition arm is a specialized tool designed to enhance the demolition range and power of standard excavators, especially for tearing down taller buildings. These arms are utilized for safely dismantling structures like buildings, bridges, and other major constructions. Some of its primary features include:

- Increased Reach: Enables the excavator to access higher elevations, typically extending up to 30 meters or more, making it suitable for tall structure demolitions.

- Robust Build: Engineered to withstand the extra forces involved in demolition, especially when paired with hydraulic tools like shears or crushers.

- Adaptability: Can be tailored to meet specific project needs, such as adjusting the arm length and ensuring compatibility with various attachments.

- Enhanced Safety: Prioritizes operator protection, with some versions offering tilting cabs and better visibility for more accurate demolitions.

This attachment is perfect for controlled demolition in densely populated urban areas and is often used alongside hydraulic tools like crushers or shears, allowing for precise demolition without endangering surrounding structures.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Some common size references

|

Excavator

(ton)

|

Total Length

(mm)

|

Transport

Height(mm)

|

Max Lift Height

(mm)

|

Limit weight of

hydraulic shear(kg)

|

Cylinder

(Ton)

|

Counterweight

(ton)

|

| 25 Ton |

16000 |

3160 |

14900 |

2000 |

20 Ton |

4T |

| 30 Ton |

18000 |

3300 |

17000 |

2000 |

20 Ton |

4.5T |

| 35 Ton |

20000 |

3300 |

19000 |

2000 |

20 Ton |

4.5T |

| 40 Ton |

22000 |

3400 |

21050 |

2000 |

20 Ton |

5T |

| 40 Ton |

24000 |

3400 |

23100 |

2000 |

20 Ton |

5T |

Excavator demolition arm supports customization, the following is general data reference.

Our three-section demolition arm can produce lengths: 16-35 meters suitable for 25-70 tons of excavators

Material: Q355B, Q690D, strong reinforcement plate.

Color: can be customized or painted according to customer requirements.

Applicable working conditions: high-rise building demolition, urban environment demolition, heavy material handling, old building renovation, building interior demolition, etc.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Zhonghe Machinery Factory Advantages of Three-section Demolition Boom

The Advantages of our demolition boom excavator:

1. The demolition arm we designed can be completely lowered, and the accessories we carry can be rotated without disassembly.

In the transport state, this arm can also rotate, while other manufacturers' designs cannot rotate and will hit the track plate.(P1)

2. The opening angle of the demolition arm can be larger, basically reaching 180 degrees, allowing the demolition height to be higher.

We have enlarged the pin of the bucket cylinder and adopted a 90-degree pin to ensure that the pin is not prone to problems under high-intensity operations(P2)

3. We currently use the best products on the market in terms of pipe design, pipe materials, and joint materials.

We strictly control the processing requirements, and must open grooves for welding and conduct trial assembly before leaving the factory to ensure precision control.

We shortened the distance between the internal ribs to increase the rigidity of the demolition arm and ensure toughness, but also increased a certain amount of weight, which improved the quality of the product.

4. Seamless precision steel pipe

5. Q690D for boom's upper and lower cover

6. Adopt 90mm pin to avoid pin breakage

7. The pipeline is hidden to avoid being smashed

8. Hydraulic pipelines section design, convenient for later maintenance

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------Product Detail Display

Excavator Demolition Boom Arm Engineering Case

Excavator demolition arm is a kind of equipment specially designed for demolition engineering, suitable for the following working conditions:

Suitable working conditions

1. Demolition of high-rise buildings

2. Demolition in urban environment

3. Precision demolition

4. Heavy material handling

5. Renovation of old buildings

6. Operation in dangerous areas

7. Demolition inside buildings

8. Bridge demolition

9. Emergency Demolition

Some Demolition Attachments With Demolition Boom

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Related building demolition attachements for excavator demolition arms

An excavator demolition boom arm can be paired with various attachments to meet different demolition needs. Here are some common attachments:

- Breaker (Hydraulic Hammer): Used for breaking concrete and other hard materials, suitable for large-scale demolition projects.

- Shears: Used for cutting steel bars and other metal structures, suitable for demolishing steel-framed buildings.

- Hydraulic Grapples: Used for grabbing and removing large pieces of material, suitable for various demolition projects.

- Rotating Shears: Used for cutting and demolishing various materials, suitable for complex demolition tasks.

- Hydraulic Hammer: Used for breaking and demolishing concrete and other hard materials, suitable for large-scale demolition projects.

- Hydraulic Shears: Used for cutting and demolishing steel bars and other metal structures, suitable for demolishing steel-framed buildings.

These attachments can be selected and combined based on specific demolition needs to improve demolition efficiency and safety.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

High precision machine of Zhonghe Machinery Manufacturers

Large Floor-Standing Double-Sided Boring and Milling Lathe:

Heightened Accuracy and Consistency: The double-sided boring and milling lathe improves the precision and uniformity of operations, guaranteeing consistent results.

Post-Welding Treatment: After welding, the machine carries out overall boring to maintain the parallelism and perpendicularity of shaft holes.

Key Applications: Mainly used for post-weld boring of the boom, small arm, and bucket, ensuring the accuracy and proper alignment of the boom.

Concurrent Boring on Both Sides: The lathe performs boring on both sides concurrently, ensuring identical precision and consistency on both sides.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

About Zhonghe Machinery Company Profile:

Kaiping Zhonghe Machinery Manufacturing Co., Ltd.

Kaiping Zhonghe Machinery Manufacturing Co., Ltd. was established in 2018. It is an enterprise integrating production and trade. It specializes in customizing different types of excavator booms arms and attachments, such as excavator long arms, demolition arms, sliding arms, 2-3 section telescopic arms, tunnel arms, standard/rock buckets, grabs, ripper, etc., which are sold well in more than 60 countries and regions.

The following are our advantages:

1. Covers an area of about 18000 square meters

2.Staff size 120 people.

3.Technical equipment (2 sets of plasma, CNC cutting machines, 3 milling machines, a set of precision floor boring machines, One set of chamfering and beveling machines, two large lathes/drilling machines, a large shot blasting workshop, a stress relief workshop, a large plate rolling machine, and a high -purity mixed gas supply station, etc.)

4.Our company offers customers a comprehensive production line of custom-designed, custom-made, and delivered products. 5.Prompt lead time:7-25 days

6.Annual production amount 600 sets of excavator booms We adhere to "Merit Quality, Sincerity Management and Customer Satisfaction", honestly greet customers from home and abroad to negotiate and cooperate with us.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

CE certification & Utility model patent certificates

Our products have been exported to over 60 countries, utilizing various transportation methods such as sea, land, and air freight. For packaging, we use either wooden crates or stretch film to secure the products. Before shipment, the goods are carefully packaged and then loaded into containers to ensure their safety during transit.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Packaging & Shipping

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

FAQ(Some frequently asked questions):

Q: Are you a manufacturer?

A: Zhonghe machinery offered a wide range of attachment parts for excavators and dozers. Such as long reach arm, demolition arm, telescopic arm, standard bucket, rock bucket, cleaning bucket, tilting bucket, etc. We know that the perfect combination of high-quality cast steel products and a moderate price is the key to the success.

Q: What are your terms of payment?

A: We prefer T/T (50/50) payment terms, and for trial orders, we recommend using Ali Credit Insurance for added security.

Q: What material is used for the demolition arm?

A: Most demolition arms are made of Q355B material. Customers require lighter weight and better quality. We can also use Q690D material, but the price will be higher.

Q: What is the difference between a demolition arm and a two-section extension arm?

A: Generally, the maximum angle of the extension arm after straightening is 150 degrees, while the angle that the demolition arm can open is about 180 degrees, which can almost be pulled into a straight line. Therefore, at the same length, the demolition arm has a higher demolition height. The two products have different focuses. The long arm focuses on deeper digging, and the demolition arm focuses on higher demolition height.

Any information, pls contact Ada!!!!

Whatsapp: +86 15322105263

Wechat/Tel: 0086 15322105263

E-mail: abby@excvatorboomarm.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!