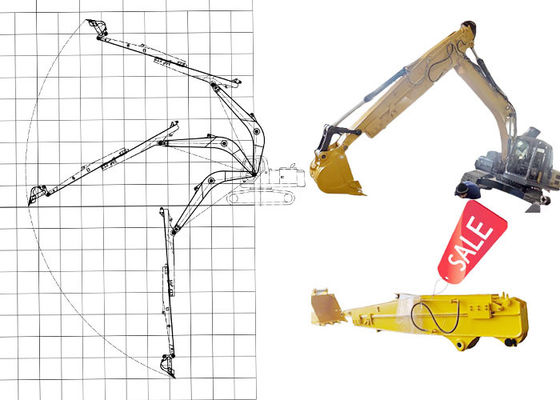

Long Demolition Boom Excavator High Reach Demolition Excavator 20.Excavator Boom for High-Rise Demolition

Product Description-----Excavator Demolition Boom

What is an excavator demolition boom arm?

An excavator demolition boom is a specialized attachment designed to extend the reach and capabilities of standard excavators for demolition tasks, especially for tall structures. These booms are used to safely dismantle buildings, bridges, and other large structures. The key features include:

1. Extended Reach: Allows the excavator to reach greater heights, often up to 30 meters or more, making it ideal for high-rise building demolition.

2. Heavy-Duty Construction: Designed to handle the additional stress and forces involved in demolition, especially when paired with attachments like hydraulic shears or crushers.

3. Customization: Demolition booms can be customized depending on the specific requirements of a project, including the length of the boom and compatibility with various attachments.

4. Safety: Enhanced operator safety is a priority, with some models featuring tilting cabs and better visibility for precision demolition.

This attachment is highly effective for controlled demolition in urban environments and is often used in conjunction with hydraulic attachments such as pulverizers, shears, or breakers. These systems allow precise dismantling without jeopardizing the structural integrity of surrounding buildings.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Some common size references

|

Excavator

(ton)

|

Total Length

(mm)

|

Transport

Height(mm)

|

Max Lift Height

(mm)

|

Limit weight of

hydraulic shear(kg)

|

Cylinder

(Ton)

|

Counterweight

(ton)

|

| 25 Ton |

16000 |

3160 |

14900 |

2000 |

20 Ton |

4T |

| 30 Ton |

18000 |

3300 |

17000 |

2000 |

20 Ton |

4.5T |

| 35 Ton |

20000 |

3300 |

19000 |

2000 |

20 Ton |

4.5T |

| 40 Ton |

22000 |

3400 |

21050 |

2000 |

20 Ton |

5T |

| 40 Ton |

24000 |

3400 |

23100 |

2000 |

20 Ton |

5T |

Excavator demolition arm supports customization, the following is general data reference.

Our three-section demolition arm can produce lengths: 16-35 meters suitable for 25-70 tons of excavators

Material: Q355B, Q690D, strong reinforcement plate.

Color: can be customized or painted according to customer requirements.

Applicable working conditions: high-rise building demolition, urban environment demolition, heavy material handling, old building renovation, building interior demolition, etc.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Zhonghe Machinery Factory Advantages of Three-section Demolition Boom

The Advantages of our demolition boom excavator:

1. The demolition arm we designed can be completely lowered, and the accessories we carry can be rotated without disassembly.

In the transport state, this arm can also rotate, while other manufacturers' designs cannot rotate and will hit the track plate.(P1)

2. The opening angle of the demolition arm can be larger, basically reaching 180 degrees, allowing the demolition height to be higher.

We have enlarged the pin of the bucket cylinder and adopted a 90-degree pin to ensure that the pin is not prone to problems under high-intensity operations(P2)

3. We currently use the best products on the market in terms of pipe design, pipe materials, and joint materials.

We strictly control the processing requirements, and must open grooves for welding and conduct trial assembly before leaving the factory to ensure precision control.

We shortened the distance between the internal ribs to increase the rigidity of the demolition arm and ensure toughness, but also increased a certain amount of weight, which improved the quality of the product.

4. Seamless precision steel pipe

5. Q690D for boom's upper and lower cover

6. Adopt 90mm pin to avoid pin breakage

7. The pipeline is hidden to avoid being smashed

8. Hydraulic pipelines section design, convenient for later maintenance

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------Product Detail Display

Excavator Demolition Boom Arm Engineering Case

Excavator demolition arm is a kind of equipment specially designed for demolition engineering, suitable for the following working conditions:

Suitable working conditions

-

Urban Demolition: Ideal for demolishing buildings and structures in urban areas where space is limited. The precision and control offered by the demolition arm ensure minimal damage to surrounding properties.

-

Industrial Demolition: Suitable for dismantling large industrial structures such as factories, warehouses, and manufacturing plants. The robust design of the demolition arm can handle heavy-duty tasks efficiently.

-

Bridge Demolition: Effective for the controlled demolition of bridges and overpasses. The arm's reach and maneuverability allow for safe and precise dismantling of these structures.

-

High-Rise Demolition: Capable of reaching high elevations, making it suitable for the demolition of tall buildings and towers. The arm can be extended to access upper floors and perform controlled demolition.

-

Concrete and Steel Structures: Designed to handle the demolition of both concrete and steel structures. The arm can be equipped with various attachments such as shears, crushers, and hammers to tackle different materials.

-

Emergency Response: Useful in emergency situations where quick and controlled demolition is required, such as after natural disasters or structural collapses.

-

Environmental Cleanup: Can be used in environmental cleanup projects where structures need to be safely dismantled and removed without causing further environmental damage.

Some Demolition Attachments With Demolition Boom

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Related building demolition attachements for excavator demolition arms

Hydraulic pulverizer: It is suitable for demolition operations such as separating reinforced concrete.

1. Made of Hardox 500, light weight and wear-resistant.

2. The oil cylinder adopts honed tube and imported HALLITE oil seal, with short working cycle and long life.

3. The pin is made of 42CRMO alloy steel with built-in oil channel, high strength and good toughness.

4. The blade is made of wear-resistant alloy steel, resistant to high temperature and deformation.

Multi crusher/Multi shear: It is suitable for the demolition of high-rise buildings in the old city renovation and the demolition of abandoned factories, solving the problem of high-altitude operations; at the same time, it prevents the occurrence of safety accidents.

1. The scissor body is made of Hardox steel plate, which ensures maximum strength and best wear resistance;

2. The oil cylinder is installed in reverse, mainly to protect the oil cylinder rod, avoid damage, and extend the service life of the oil cylinder.

Double cylinder shear: The double cylinder shear adopts a specially made reinforced slewing bearing. The teeth of the slewing bearing are processed with high frequency, so it has better wear resistance and longer service life. This reinforced slewing bearing has a greater load-bearing capacity and can withstand loads in various directions at the same time. It is the one with the largest load-bearing capacity among slewing bearing products of the same level and can be used in harsh working conditions such as high-altitude demolition.

Rock hammer/breaker hammer: Suitable for mining, construction, demolition, highways, railways, ships, metallurgy, municipal gardens, etc. The impact energy-enhanced structure design of the breaker hammer; it adopts the optimal design concept, increases the piston and cylinder stroke, and uses the same diameter of the piston and drill rod, so that the breaker hammer and the main machine match better, reasonably utilizes the highest output energy, saves energy, and achieves the highest work efficiency; it is manufactured using high-quality materials and special precision technology.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

High precision machine of Zhonghe Machinery Manufacturers

Large Floor-Standing Double-Sided Boring and Milling Lathe:

- Improved Accuracy and Consistency: The double-sided boring and milling lathe enhances the precision and uniformity of operations, ensuring consistent results.

- Post-Welding Processing: After the welding process, the machine performs overall boring, ensuring the parallelism and perpendicularity of shaft holes.

- Primary Applications: Primarily used for post-weld boring of the boom, small arm, and bucket, ensuring the accuracy and proper alignment of the boom.

- Simultaneous Boring on Both Sides: The lathe performs boring on both sides at the same time, guaranteeing identical precision and consistency on both sides.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

About Zhonghe Machinery Company Profile:

Kaiping Zhonghe Machinery Manufacturing Co., Ltd.

Kaiping Zhonghe Machinery Manufacturing Co., Ltd. was established in 2018. It is an enterprise integrating production and trade. It specializes in customizing different types of excavator booms arms and attachments, such as excavator long arms, demolition arms, sliding arms, 2-3 section telescopic arms, tunnel arms, standard/rock buckets, grabs, ripper, etc., which are sold well in more than 60 countries and regions.

The following are our advantages:

1. Covers an area of about 18000 square meters

2.Staff size 120 people.

3.Technical equipment (2 sets of plasma, CNC cutting machines, 3 milling machines, a set of precision floor boring machines, One set of chamfering and beveling machines, two large lathes/drilling machines, a large shot blasting workshop, a stress relief workshop, a large plate rolling machine, and a high -purity mixed gas supply station, etc.)

4.Our company offers customers a comprehensive production line of custom-designed, custom-made, and delivered products. 5.Prompt lead time:7-25 days

6.Annual production amount 600 sets of excavator booms We adhere to "Merit Quality, Sincerity Management and Customer Satisfaction", honestly greet customers from home and abroad to negotiate and cooperate with us.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

CE certification & Utility model patent certificates

Our products have been exported to over 60 countries, utilizing various transportation methods such as sea, land, and air freight. For packaging, we use either wooden crates or stretch film to secure the products. Before shipment, the goods are carefully packaged and then loaded into containers to ensure their safety during transit.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Packaging & Shipping

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

FAQ(Some frequently asked questions):

Q: Are you a manufacturer?

A: Zhonghe machinery offered a wide range of attachment parts for excavators and dozers. Such as long reach arm, demolition arm, telescopic arm, standard bucket, rock bucket, cleaning bucket, tilting bucket, etc. We know that the perfect combination of high-quality cast steel products and a moderate price is the key to the success.

Q: What material is the excavator demolition boom made of?

A: Shaogang Q355B, Shaogang's material has the advantages of good toughness, high welding performance, and not easy to crack. Q355B has good welding performance and can be processed at room temperature. The standard arm material of the host manufacturer is also Q355B, which is easier to purchase on the market and the subsequent maintenance cost is also simple. If the customer's working conditions are bad, we will also use Q690 material, the long arm will be made lighter and more efficient

Q: Why choose Zhonghe over other companies?

A: We offer a highly skilled production and design team that delivers high-quality, customized solutions tailored to each customer’s needs. Our commitment to precision and customer service has earned us a strong reputation in China, with annual sales consistently ranking among the top in the industry.

Q: What are your terms of payment?

A: We prefer T/T (50/50) payment terms, and for trial orders, we recommend using Ali Credit Insurance for added security.

Any information, pls contact Ada!!!!

Whatsapp: +86 15322105263

Wechat/Tel: 0086 15322105263

E-mail: abby@excvatorboomarm.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!