--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

|

Excavator

(ton)

|

Total Length

(mm)

|

Max Radius

(mm)

|

Max Depth

(mm)

|

Max Unload Height

(cbm)

|

Max Height

(mm)

|

Bucket Capacity

(mm)

|

| 11-15T |

13000 |

11200 |

9000 |

7550 |

9000 |

0.15-0.3 |

| 20-25T |

15400 |

14500 |

11300 |

10400 |

12600 |

0.4-0.6 |

| 20-30T |

18000 |

17300 |

13000 |

11800 |

14000 |

0.4-0.7 |

| 35-40T |

20000 |

19200 |

14900 |

12900 |

15200 |

0.4-0.7 |

| 40-45T |

22000 |

21300 |

16000 |

14000 |

17000 |

0.5-1 |

| 40-50T |

24000 |

21300 |

17900 |

15200 |

18100 |

0.5-1.1 |

Zhonghe Machinery Long Arm:

1. Because our long arms are customized and designed according to the size of the excavator, they are suitable for all excavator brands, such as Hitachi, Carter, Sumitomo, Kobelco, Kubota, Komatsu, Kato, Doosan, Liebherr, Lingong, Longgong, etc.

2. Applicable tonnage and length of long arms: suitable for 6-120 tons excavators, 7-35 meters long arms

3. Support ODM, OEM, such as color, size, logo, etc. can be customized

4. Material: Q355B, Q690D, Q550, etc.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Zhonghe Factory Advantages of Long Reach Boom/Long Arm:

What is the purpose of a long arm plate bevel?

The purpose of a long arm plate bevel is to facilitate the welding process, ensuring a stronger and more reliable weld that extends through the full thickness of the material. Here are the key reasons for using a bevel on a long arm plate:

-

Improved Weld Penetration: As you mentioned, welding machines typically have a depth of fusion that is less than the thickness of the plate. A bevel allows the welding arc to reach further into the material, achieving better penetration and ensuring that the weld fills the entire joint.

-

Preventing Weld Cracking: Without a bevel, the weld may not penetrate fully, leaving a weak spot in the weld that could lead to cracking under stress. A proper bevel ensures that the weld is continuous and free of defects that could cause future failures.

-

Reducing Welding Time: A beveled edge can reduce the amount of material that needs to be melted, which can decrease the time required to complete the weld.

-

Enhancing Weld Quality: The bevel provides a consistent edge for the welder to work with, which can lead to a more uniform and aesthetically pleasing weld.

-

Mechanical vs. Manual Beveling: Mechanically cutting bevels is generally more precise than manual methods. This precision is critical for ensuring the quality of the weld. A mechanically cut bevel provides a cleaner, more uniform edge that can be more easily and consistently welded.

Factories that use mechanical beveling over manual beveling often produce products with higher quality and consistency. The mechanical process reduces human error and provides a more reliable bevel that is critical for structural integrity, especially in heavy-duty equipment like excavator long arm plates.

We make bevels mechanically, while other factories make bevels manually (as shown in the picture)

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Comparison Between Other Products And Ours

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

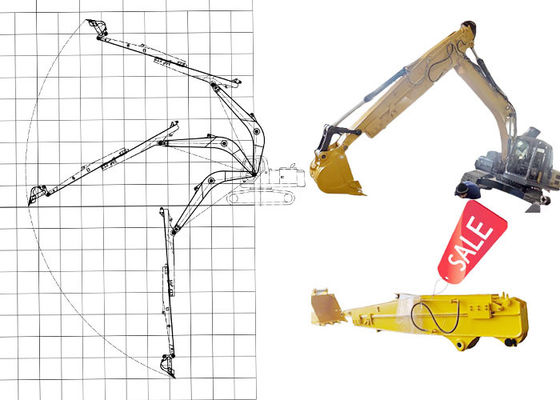

Working Scene of Excavator Long Reach Boom Arm

Main features of extended excavator arms:

Wider operating range: Compared with standard excavator arms, extended arms can dig deeper or farther, suitable for large areas or high-altitude operations.

Wide application: Extended arms are widely used in river dredging, mountain restoration, high-rise building demolition and other fields.

Strong stability: Although the extended arm expands the excavation range, its design maintains the balance and operational stability of the equipment, which is particularly suitable for large-scale operations.

Adapt to complex working conditions: In underwater operations or difficult demolition projects, extended arms can achieve precise operations and adapt to various complex environments.

Customizable design: Extended arms can usually be customized according to project requirements, such as arm length, strength, required special accessories, etc.

Some Pictures----Long Arm for Hitachi 1200

Key Features of the 7-35m Long-Reach Boom for All Excavators:

-

Extended Reach Options: Available in lengths ranging from 7 to 35 meters, the long-reach boom significantly enhances the horizontal and vertical reach of excavators, making them ideal for tasks like deep excavation, dredging, and high-reach demolition.

-

Wide Compatibility: Designed to fit excavators ranging from 6 to 120 tons, the boom can be customized to work with various excavator models, enhancing their versatility.

-

High-Strength Materials: Built with durable materials such as Q355B or Q690D steel, ensuring strength, stability, and durability in demanding environments.

-

Precision Manufacturing: The boom incorporates features like integral forming for the middle sleeve and reinforced boom seat sleeves made from 45# steel, improving overall performance and longevity.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

High precision machine of Zhonghe Machinery Manufacturers

Large Floor-Standing Double-Sided Boring and Milling Lathe:

- Improved Accuracy and Consistency: The double-sided boring and milling lathe enhances the precision and uniformity of operations, ensuring consistent results.

- Post-Welding Processing: After the welding process, the machine performs overall boring, ensuring the parallelism and perpendicularity of shaft holes.

- Primary Applications: Primarily used for post-weld boring of the boom, small arm, and bucket, ensuring the accuracy and proper alignment of the boom.

- Simultaneous Boring on Both Sides: The lathe performs boring on both sides at the same time, guaranteeing identical precision and consistency on both sides.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

About Zhonghe Machinery Company Profile:

Kaiping Zhonghe Machinery Co., Ltd., founded in 2018, is a company that integrates both manufacturing and trading, with a focus on producing customized excavator boom arms and attachments. Located in Cuishanhu New District, Kaiping City, Jiangmen, Guangdong Province, China, the company operates a 21,000 square meter steel-structured facility equipped with advanced precision machinery. Our team consists of more than 100 skilled professionals, including 50 welders with over 7 years of experience, 30 senior designers, and a high-tech R&D team with over 10 years of expertise in custom solutions and holding 100+ technical patents. With a robust production system (6+ years of quality and cost control) and a dedicated service team, we are capable of producing up to 800 excavator boom arms annually.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

CE certification & Utility model patent certificates

Our products have been exported to over 60 countries, utilizing various transportation methods such as sea, land, and air freight. For packaging, we use either wooden crates or stretch film to secure the products. Before shipment, the goods are carefully packaged and then loaded into containers to ensure their safety during transit.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Packaging & Shipping

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

FAQ(Some frequently asked questions):

Q: Are you a manufacturer?

A: Zhonghe machinery offered a wide range of attachment parts for excavators and dozers. Such as long reach arm, demolition arm, telescopic arm, standard bucket, rock bucket, cleaning bucket, tilting bucket, etc. We know that the perfect combination of high-quality cast steel products and a moderate price is the key to the success.

Q: What material is the excavator long arm made of?

A: Shaogang Q355B, Shaogang's material has the advantages of good toughness, high welding performance, and not easy to crack. Q355B has good welding performance and can be processed at room temperature. The standard arm material of the host manufacturer is also Q355B, which is easier to purchase on the market and the subsequent maintenance cost is also simple. If the customer's working conditions are bad, we will also use Q690 material, the long arm will be made lighter and more efficient

Q: Why choose Zhonghe over other companies?

A: We offer a highly skilled production and design team that delivers high-quality, customized solutions tailored to each customer’s needs. Our commitment to precision and customer service has earned us a strong reputation in China, with annual sales consistently ranking among the top in the industry.

Q: What are your terms of payment?

A: We prefer T/T (50/50) payment terms, and for trial orders, we recommend using Ali Credit Insurance for added security.

Any information, pls contact Sophia!

this is my contact way directly

Sophia W/A: +86 18127591702

Mail: sophia@excavatorboomarm.com

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!