--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

|

Excavator

(ton)

|

Total Length

(mm)

|

Max Radius

(mm)

|

Max Depth

(mm)

|

Max Unload Height

(cbm)

|

Max Height

(mm)

|

Bucket Capacity

(mm)

|

| 11-15T |

13000 |

11200 |

9000 |

7550 |

9000 |

0.15-0.3 |

| 20-25T |

15400 |

14500 |

11300 |

10400 |

12600 |

0.4-0.6 |

| 20-30T |

18000 |

17300 |

13000 |

11800 |

14000 |

0.4-0.7 |

| 35-40T |

20000 |

19200 |

14900 |

12900 |

15200 |

0.4-0.7 |

| 40-45T |

22000 |

21300 |

16000 |

14000 |

17000 |

0.5-1 |

| 40-50T |

24000 |

21300 |

17900 |

15200 |

18100 |

0.5-1.1 |

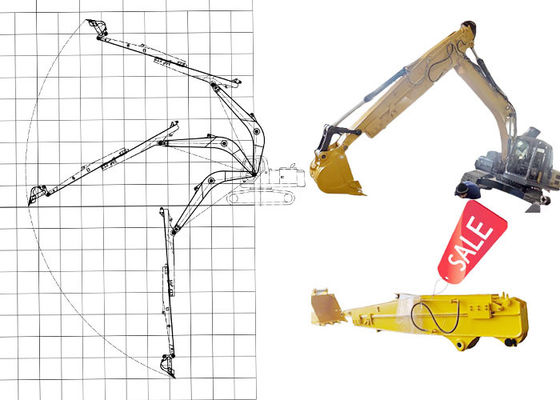

Zhonghe Machinery long reach Arm:

1. Because our long arms are customized, they are designed according to the size of the excavator, so they are suitable for all excavator brands, such as Hitachi, Carter, Sumitomo, Kobelco, Kubota, Komatsu, Kato, Doosan, Liebherr, Lingong, Longgong, etc.

2. Long arms are suitable for tonnage and length: suitable for 6-120 tons excavators, 7-35 meters long arms

3. Support ODM, OEM, such as color, size, logo, etc. can be customized

4. Material: Q355B, Q690D, Q550, etc.

--------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Zhonghe Factory Advantages of Long Reach Boom/Long Arm:

1.These 4 main weld passes, they are all double layers. We ensure the welding melts to the whole plate.

2. It can make the pass more firm and less likely to crack. 3. Here you can see the pass is full and very smooth.Our welding worker is skillful and have more than 10 years working experience, very professional.

4. Seamless precision steel pipe

5. Three layers and four passes welding

6.Lubrication concentrate system. There are 5 lubrication pipes, all concentrated here, making it easy and convenient for operators to add lubricating oil.

We use double-layer reinforcement plates at the boom base, making our long arms more durable and stronger than other suppliers.

1. The parts prone to cracking have been reinforced, and the box inside the ear seat has been reinforced. 2. The connection between the end of boom and the box has been reinforced. 3. The ear seat of the arm has been reinforced and the design mechanism has been changed.

What is the role of beveling the long arm plate?

The melting depth of the welding machine commonly used in the industry is only 3mm thick. The plate thickness of our long arm is at least 8mm. If the beveling is not opened, the welding machine will not be able to penetrate the entire weld, so the welding effect will be poor, and the weld cracking and other problems will occur later.

We use machinery to make the bevel, while other factories use manual bevel (as shown in the picture)

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Comparison Between Other Products And Ours

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Working Scene of Excavator Long Reach Boom Arm

The excavator extended arm is mainly suitable for the following special working conditions:

1. High-altitude demolition:

During the demolition of buildings, especially the demolition of high-rise buildings or large-volume structures, the standard excavator arm is not long enough. The extended arm can increase the height and range of the demolition operation and avoid the safety hazards of close-range demolition.

2. Deep pit excavation:

For working conditions such as river dredging and deep foundation pit excavation, the extended arm of the excavator can better perform deep operations, without the need for the excavator to approach dangerous areas, thereby ensuring the safety of equipment and personnel.

3. River cleaning and dredging:

In the work of dredging the waterside or river channel, the extended arm can effectively increase the operating range, allowing the excavator to operate at a distance without entering the water, reducing the risk of equipment damage.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

High precision machine of Zhonghe Machinery Manufacturers

Large floor-standing double-sided boring and milling lathe:

Double-sided boring and milling machine can improve accuracy and consistency. After the overall welding is completed, the overall hole is bored to ensure the parallelism and verticality of the shaft hole. It is mainly responsible for the post-welding boring of the large and small arms and buckets to ensure the accuracy of the arm. Since the boring pin operation on both sides of the double-sided boring machine is carried out simultaneously, the processing accuracy and consistency of both sides can be guaranteed.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

About Zhonghe Machinery Company Profile:

Kaiping Zhonghe Machinery Co.,Ltd. established in 2018, it is a combination of manufacturing and trading, specializing in customizing different kinds of excavator boom arms and attachments. We are located in cuishanhu New District. Kaiping cityJiangmen City. Guangdong Province, China. We boast a 21000m3 steel structure workshop with a large number of high precision processing equipment and a strong and cohesive team of over 100 experienced technical staff. 50 welding workers with over 7 years experience. 30 senior designers, and a high-tech R&D team(10+ years on customization.100+technical patents), strict production system(6+ years quality control and cost control) and warm-hearted service team. Our annual output of various types of excavator boom arms can reach up to 800 sets.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

CE certification & Utility model patent certificates

Our products have been sold to more than 60 countries, and our transportation methods include sea transportation, land transportation, and air transportation. Our packaging is wooden box packaging or stretch film packaging. The goods will be packed before shipment and then loaded into the container to ensure the safety of the goods.

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Packaging & Shipping

------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

FAQ(Some frequently asked questions):

Q: Are you a manufacturer?

A: Zhonghe machinery offered a wide range of attachment parts for excavators and dozers. Such as long reach arm, demolition arm, telescopic arm, standard bucket, rock bucket, cleaning bucket, tilting bucket, etc. We know that the perfect combination of high-quality cast steel products and a moderate price is the key to the success.

Q: Why choose Zhonghe over any other companies?

A: We have a professional production team and design team to provide each customer with high-quality and personalized customer service to ensure correctness, so we have good reputation in China, and our annual sales are among the best in our country.

Q: What are your terms of payment?

A: We prefer T/T (50/50) through Ali Credit Insurance as a trial order.

Q: What material is the excavator long arm made of?

A: Shaogang Q355B, Shaogang's material has the advantages of good toughness, high welding performance, and not easy to crack. Q355B has good welding performance and can be processed at room temperature. The standard arm material of the host manufacturer is also Q355B, which is easier to purchase on the market and the subsequent maintenance cost is also simple. If the customer's working conditions are bad, we will also use Q690 material, the long arm will be made lighter and more efficient

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!