The production of excavator long arms is a critical process in the construction and heavy machinery industry. Long arms are designed to extend the reach of excavators, allowing for greater digging depth and improved performance in challenging environments.

Key Considerations in Production:

Material Selection: High-strength steel is often used to ensure durability and withstand heavy loads. The choice of material affects both the weight and strength of the long arm.

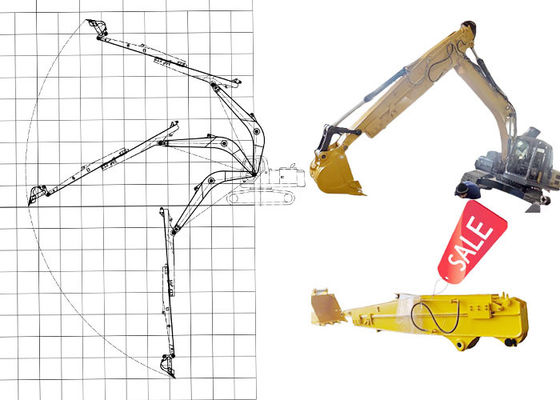

Engineering Design: Advanced CAD software is utilized to create precise designs that optimize the arm's geometry for strength and efficiency. Structural integrity is paramount to prevent failure during operation.

Manufacturing Techniques:

Welding: High-quality welding techniques are employed to join various components, ensuring structural stability.

Machining: Precision machining is crucial for creating the necessary fittings and mounting points.

Testing and Quality Assurance: Each long arm undergoes rigorous testing to ensure it meets safety standards and performance specifications. This includes load testing and fatigue analysis.

Customization: Many manufacturers offer customization options to meet specific project requirements, allowing for tailored lengths and features based on the intended application.

Conclusion

The production of excavator long arms is a complex process that combines advanced engineering, quality materials, and precise manufacturing techniques. As construction demands evolve, so do the innovations in long arm design, enhancing the versatility and efficiency of excavators in various applications.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!