Long Reach Boom Excavator 15m 18m Dredging Digging Construction

Features of one set of Zhonghe Machinery excavator long reach arm for excavator:

Sales Annual Amount: 300 sets+

1. Extended Reach

- Designed to extend the operational range of excavators, allowing for deeper digging and greater outreach.

2. Durable Construction

- Made from high-strength steel, ensuring durability and resistance to wear and tear in harsh working conditions.

3. Enhanced Stability

- Features design elements that improve the stability of the excavator during extended operations, reducing the risk of tipping.

4. Easy Installation

- Simple and quick installation process, compatible with a variety of excavator models.

5. Versatile Applications

- Ideal for a range of applications, including dredging, digging deep trenches, and working in tight spaces.

6. Improved Hydraulics

- Optimized hydraulic systems for better performance, allowing for smoother operation and increased productivity.

7. Customizable Options

- Available in different lengths and configurations to suit specific project needs or machine specifications.

8. Reduced Maintenance

- Designed for lower maintenance requirements, with features that minimize wear on the excavator.

9. Safety Features

- Incorporates safety mechanisms to protect both the operator and the machinery during operation.

Specifications of one set of excavator long arm:

| Excavator Model(m) |

Counterweight (ton) |

Bucket capacity (cbm) |

Boom(m) |

Length(m)

19-20

|

| Bucket cylinder(ton) |

Arm(m) |

| 30-36T |

0 |

0.6 |

11 |

| 20T |

9 |

| 37-39T |

0 |

0.6 |

11 |

| 20T |

9 |

| 40-47T |

0 |

1 |

11 |

| 25T |

9 |

| 25-28T |

3.5T |

0.4 |

12 |

21-22 |

| 12T |

10 |

| 30-33T |

2.5T |

0.4 |

12 |

| 12T |

10 |

| 35-39T |

1.5T |

0.6 |

12 |

| 20T |

10 |

| 40-47T |

0 |

0.8 |

12 |

| 20T |

10 |

| 30-35T |

3.5T |

0.4 |

13 |

23-24 |

| 12T |

11 |

| 35-39T |

2T |

0.4 |

13 |

| 12T |

11 |

| 40-47T |

0 |

0.6 |

13 |

| 20T |

11 |

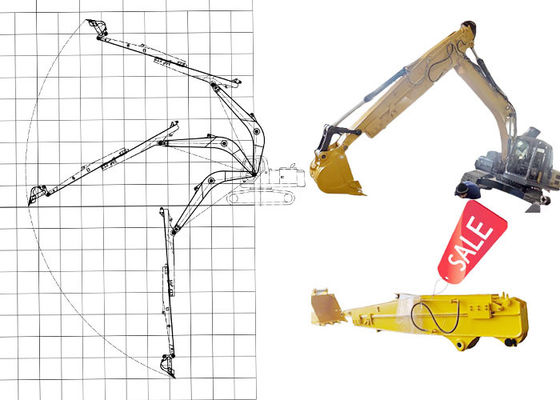

Model drawings of one set of long excavator boom:

Plate thickness of one set of long reach boom excavator:

Excellent design of Zhonghe Machinery long reach boom arm:

* Every plates of excavator long arm are beveled before welding which enhances the welding strong, not easy cracking

* Using better welding wire--Jinqiao Welding wire

* Seamless pipelines -- there is no scrap in the pipelines

* Rational internal ribs arrangment--ensure the long reach boom excavator is strong enough and longer life-span

* The boom end sleeve of long excavator boom we use is Graphite alloy copper sleeve, other sleeve we use is steel sleeves

Professional production process of Zhonghe Machinery's excavator long boom arm for sale:

* Precision Machines --- lessen deviation of production

* Experienced Staffs --- make sure every details are good enough

* Comprehensive testing --- long reach excavator reach is full tested before sending to clients

1. 14000㎡ Workshop

Our company has more than 14000㎡ workshop with a large number of high precision processing equipments such as

* Large double-sided floor boring machine---more accurate of the production process of long boom arm excavator

* CNC plasma cutting machine---lessen deformation of steel plates.

* Automatic edge milling machine---enhance welding bead, make sure that the plates are fulled beveled and the strong welding

Why our long reach arm for excavator excel other suppliers?

Our team show:

* Professional *Experienced

Welcome to contact us!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!